Better products and simpler supply chains

Automation improves product quality, speeds production, reduces waste and shortens supply chains.

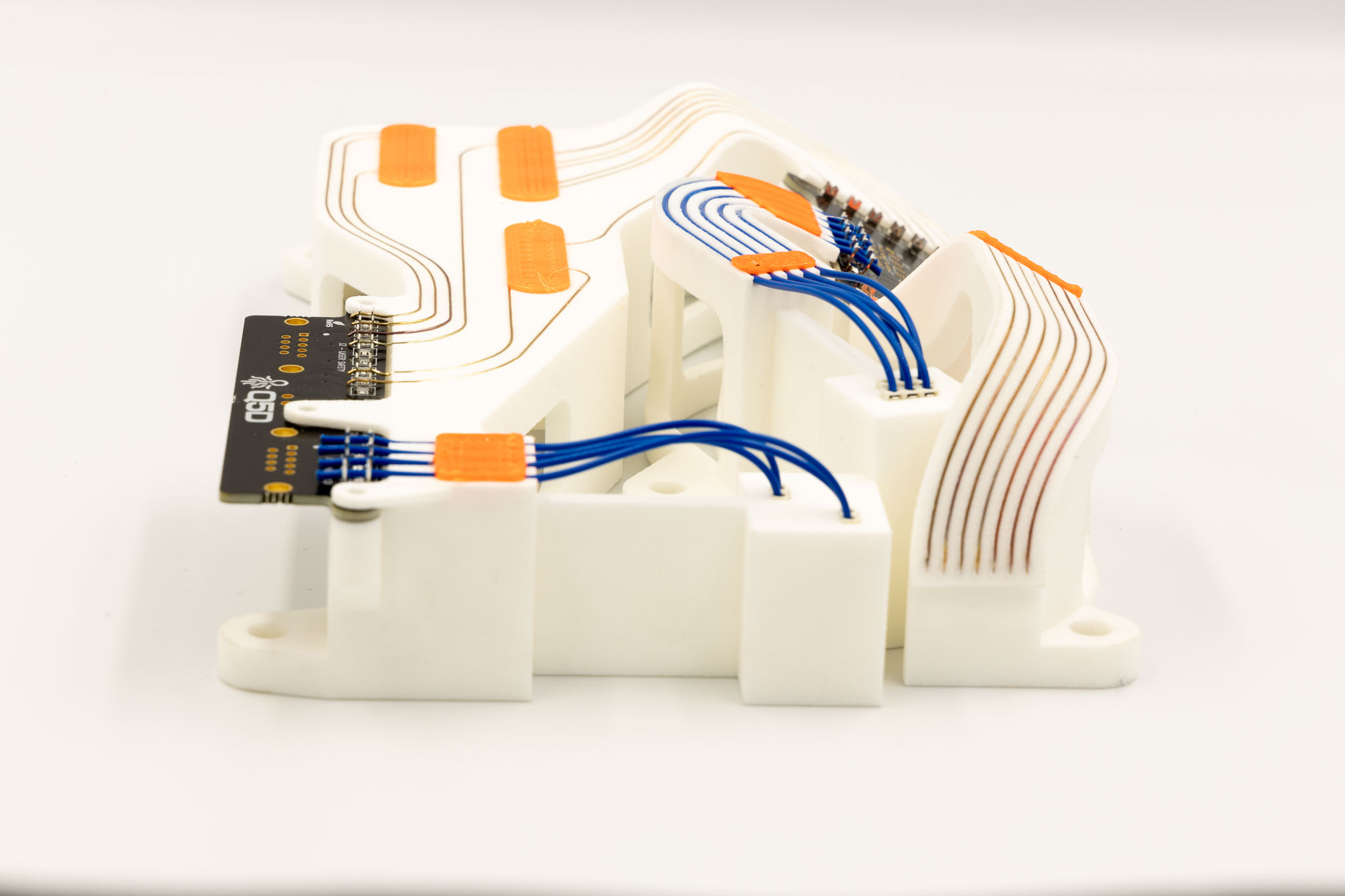

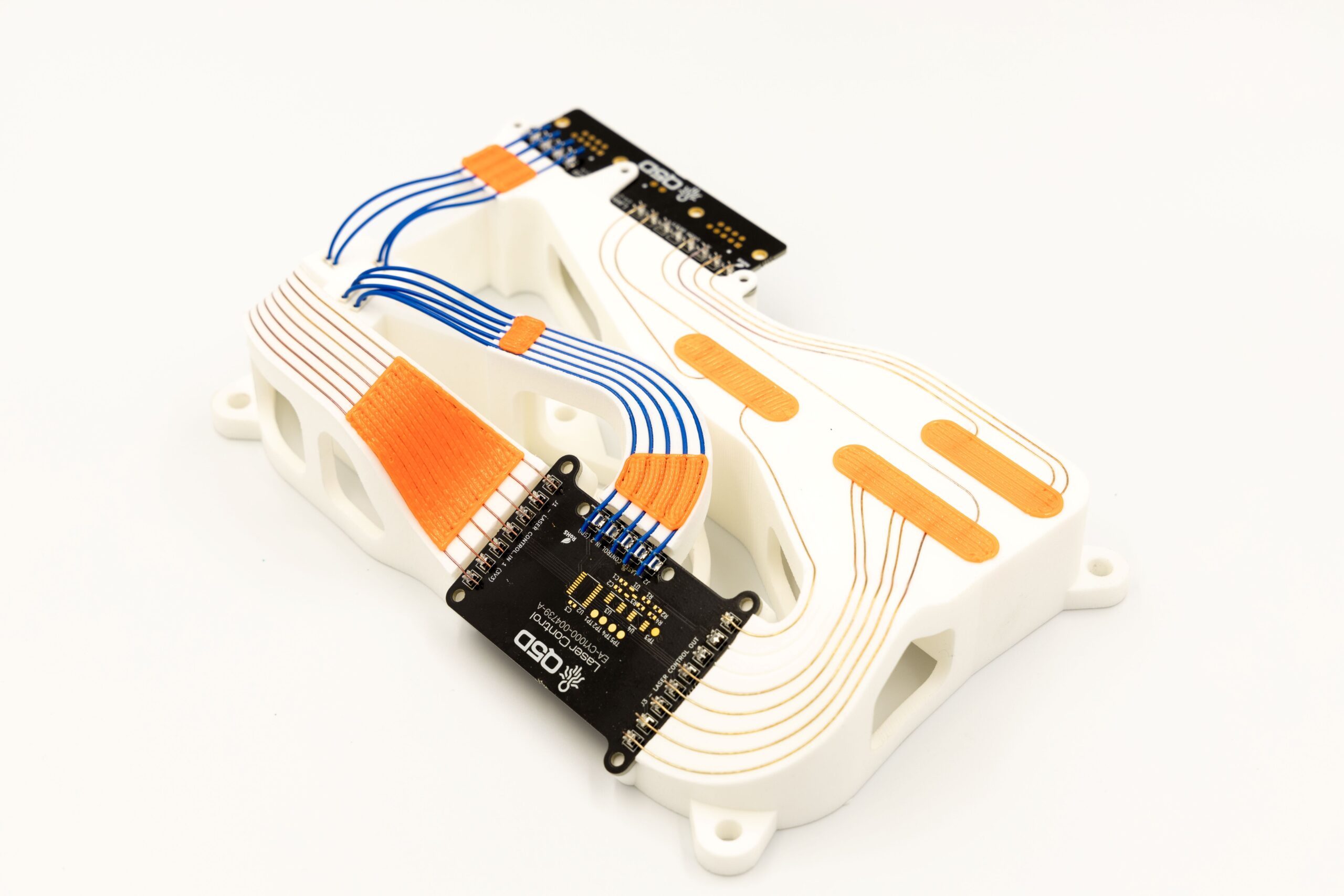

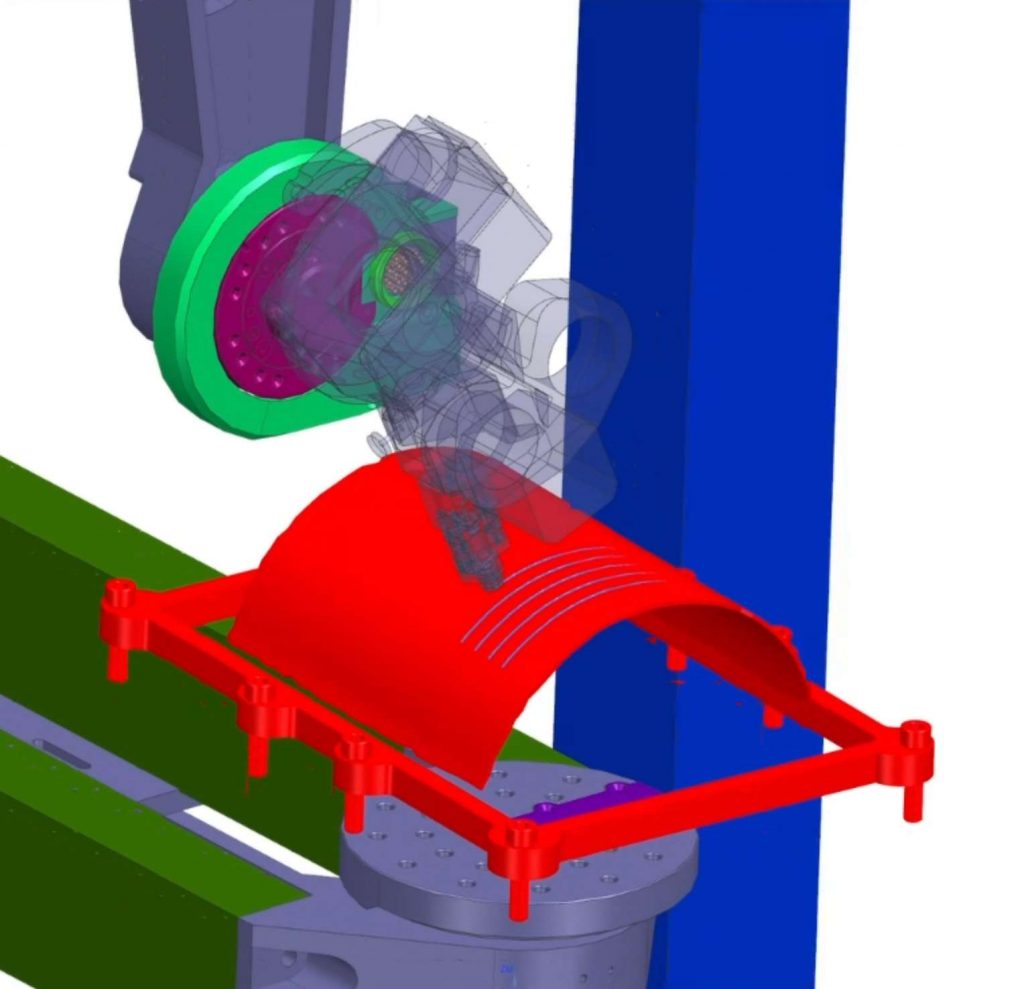

Save space, reduce weight & create new product options

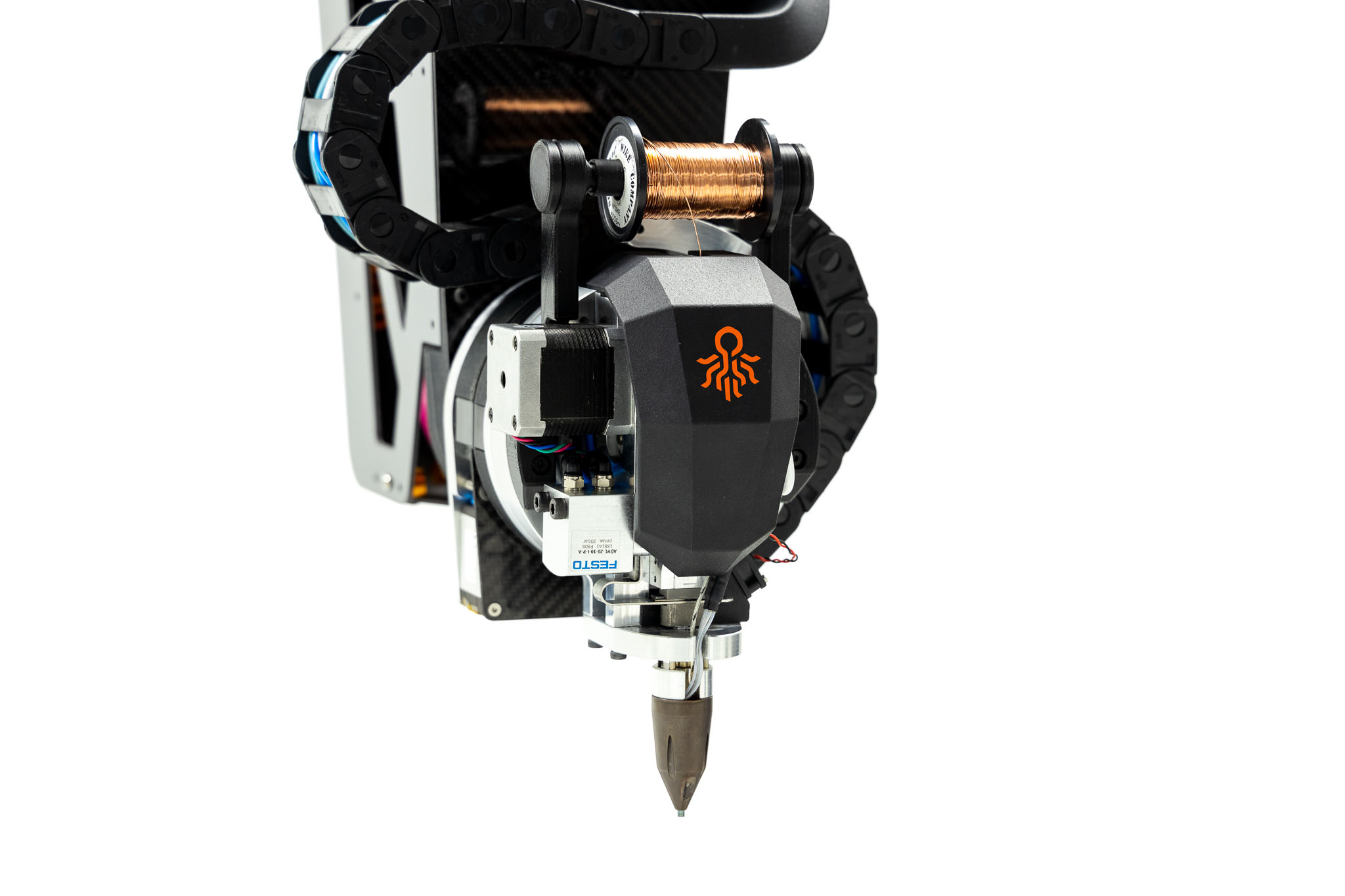

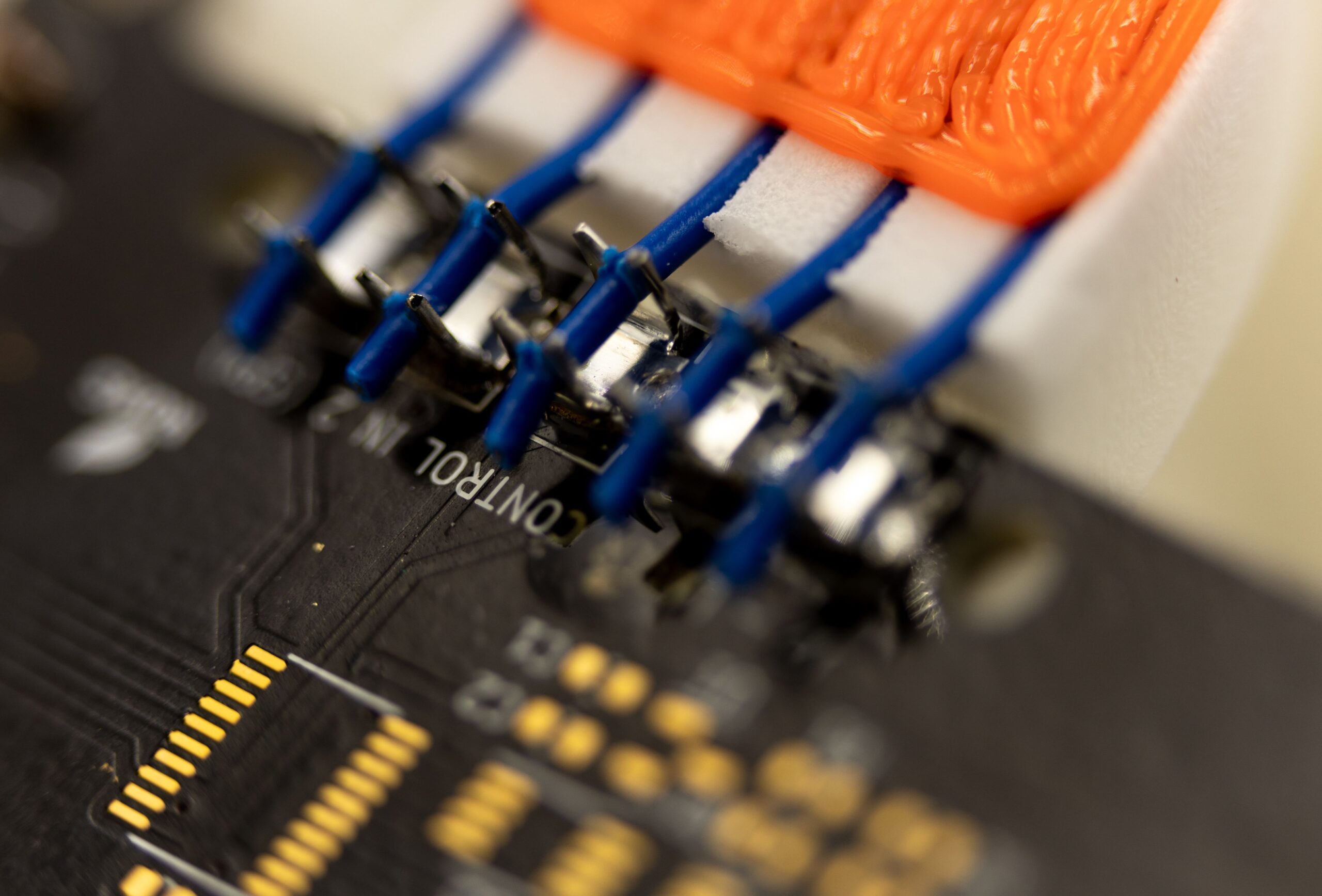

Electrical Function Integration (EFI)

Hardware as a Service

We want you to be able to focus on making your products.

We’re constantly updating our software and hardware products and developing our services. We want all our customers to be able to employ the benefits. Our lease packages encompass the software, hardware and services needed to maintain your production, and this Hardware as a Service (HaaS) approach means that customers always enjoy the latest developments.

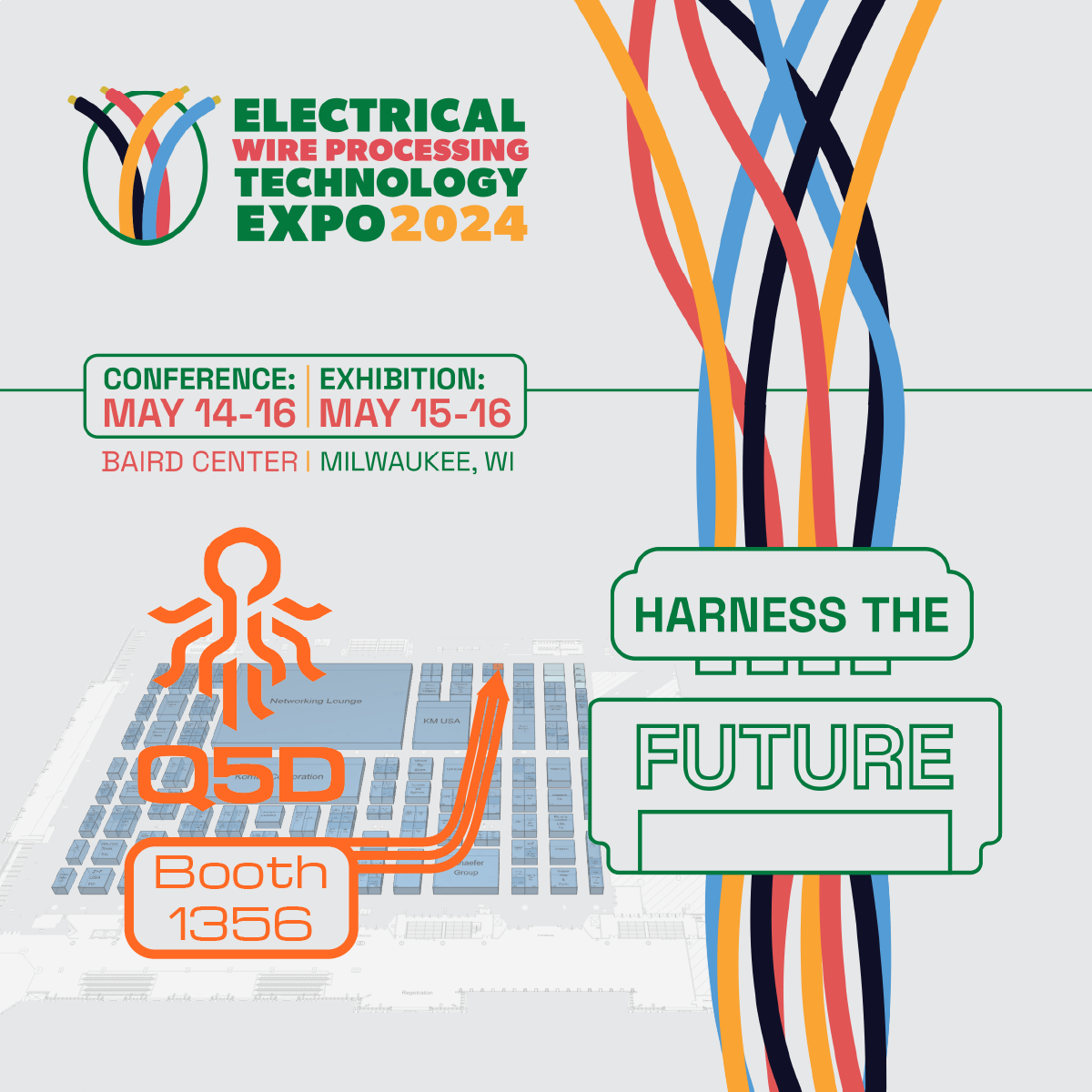

Come see us

Come and see demonstrations, meet the team and discuss your projects.

Find Q5D at Booth 1356 Why Attend the Electrical Wire Processing Technology Expo (EWPTE)? https://www.electricalwireshow.com/ [...]

Q5D have been invited to join the UK trade visit to Singapore from 16-20 October. This is organised by InnovateUK [...]

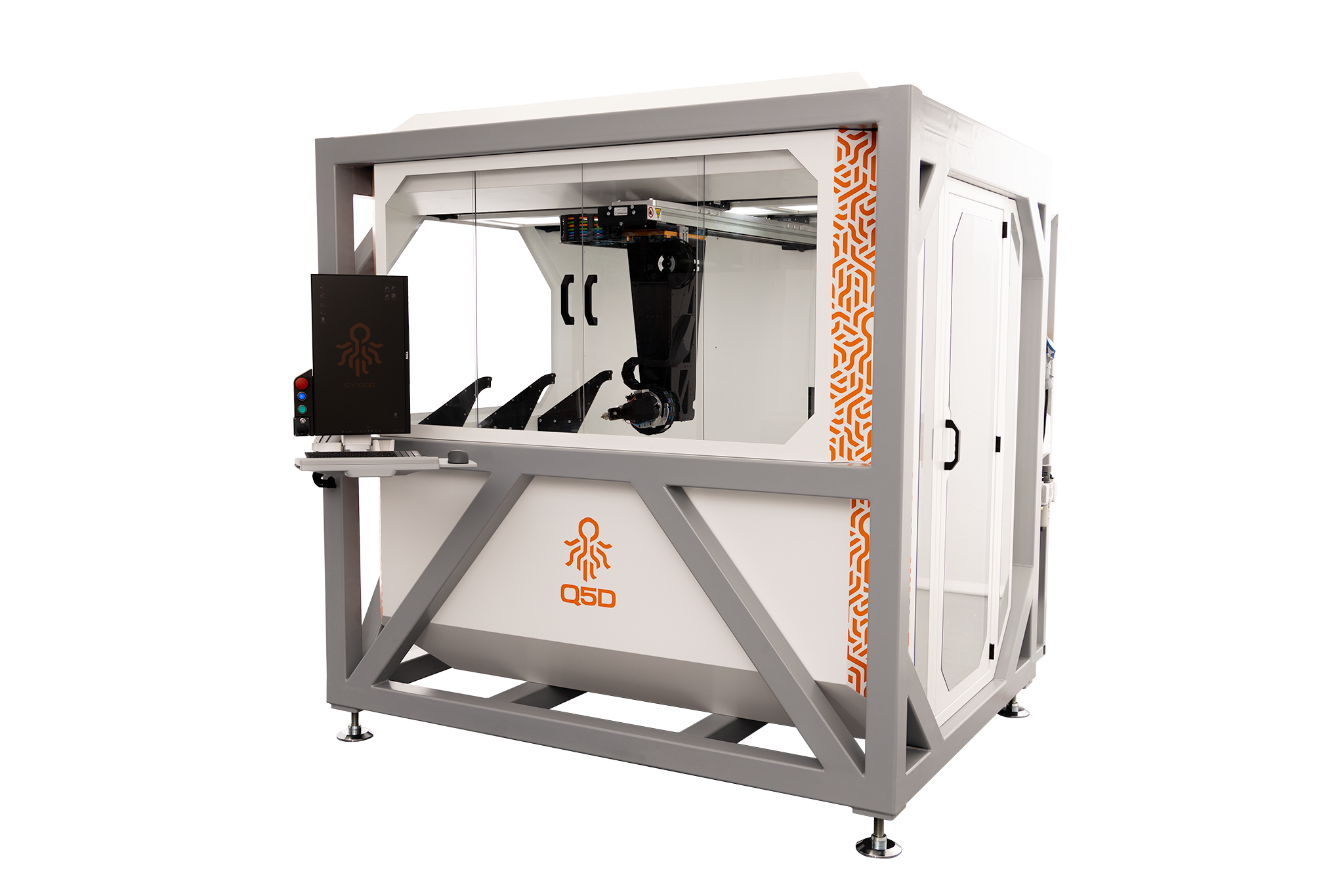

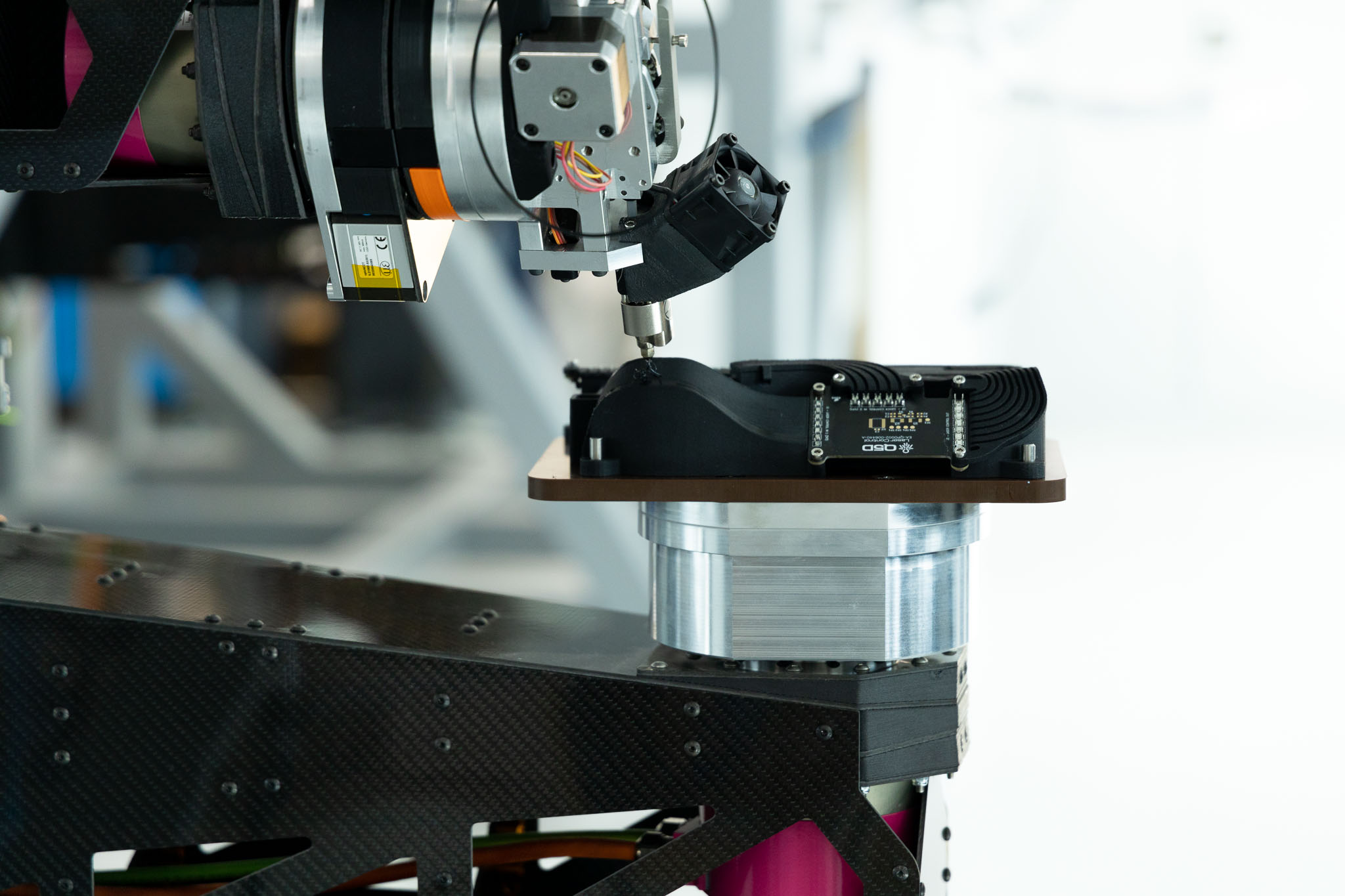

Bristol, 11th October, 2023 - Q5D will give the first public demonstration of its CY1000, 5-axis additive manufacturing robotic cell [...]

Contact